|

| Google Images |

Tuesday, April 30, 2013

Owner Manual 2012 Chevrolet Camaro

Friday, April 26, 2013

2012 Chevrolet Corvette Grand Sport GS Owners Manual User Pdf

|

| Google Images |

Thursday, April 11, 2013

Automatic Transmission

Wednesday, April 10, 2013

Comparison between MacPherson Double Wishbone Suspension System

As we have seen, both suspension systems have their own plus points and limitations. To conclude, double wishbones may perform better, but the MacPherson struts would prove to be more affordable in the long run.

Sunday, April 7, 2013

Volvo MD5A Marine diesel engine WORKSHOP MANUAL

The SI-system is now being applied within industry in Europe, This manual contains the new SIunits. The units used previously however, are also stated but in brackets. Drain the cooling water and the oil from the engine. Clean externally afterwards. Loosen the water hose between the gearbox and the sea -water pump and remove the gearbox. 3. Remove the rocker cover and the fuel pipe between the pump and the injector and unscrew the rocker gear. Note! Pull the rocker gear straight up since it is centred with a guide pin 1. The other hole 2 is an oil channel.

Download: Volvo MD5A Marine diesel engine WORKSHOP MANUAL

Saturday, April 6, 2013

The Way to Replace an Engine Mount

However, if you actually need to replace the engine mount, Ill give you a simple guide to resolve it. As we know, each engine mount can be different from another, so this is just a general guideline. Since most mounts share the same characteristics so this guide would be a good start.

Friday, April 5, 2013

1991 Mitsubishi GTO 3000GT Repair Service Manual

Download: 1991 Mitsubishi GTO 3000GT Repair Service Manual

Thursday, April 4, 2013

2005 Hyundai Santa Fe Owners Manual

Download: 2005 Hyundai Santa Fe Owners Manual

Wednesday, April 3, 2013

Audi A3 City Lights for the US A3 with Bi Xenon Headlamps

Until US automotive lighting regulations began to be reformed in the late 1980s and 1990s, headlights had to be physically separated from other lights, like parking lights and turn signals. Therefore, city lights were not permitted in US-spec headlamps. Under current regulations, though, lights may be combined into common lens/reflector assemblies, as long they meet their individual requirements. That means that city lights are permitted, and they may even serve as front parking lights if they otherwise meet the right criteria. Some VWs (like the Mk4 Golf/GTI) are good examples of this.

The halogen and xenon/halogen headlamps that Audi installs in the US A3s do not have city light bulbs at all. The A3 sidemarkers are curved to be visible from the front as well, so Audi got the car approved with only the US-required amber sidemarker/relfector lights as front parking lights. On the cars with bi-xenon headlamps, city lights are present in the inner (DRL) reflector. They are wired internally within the headlamp assembly, but the wiring harness that plugs into the headlamp assembly does not have a wire going to the pin that powers the city light bulbs.

Some simple circuit tracing determined that Pin 10 on the headlamp plug goes to the city lights. All that is needed is to run a new circuit from the +12v of the left & right sidemarkers to Pin 10 of the respective headlamp plugs.

Teminology note: The lights on the front bumper are sidemarkers. They come on with the parking lights and headlights, are required to illuminate amber, and also serve as the required amber passive reflectors. The lights farther back on the fender are not sidemarkers, they are repeater turn signals. They are required in many countries; in the US they are permissable, but not required.

Materials:

You will need a minimum of 1 repair wire from Audi, which can be obtained from your parts department. They are a length of wire with a connector (the same one) on each end. There are various connectors, for this project you will need part number 000-979-133-A, a female blade connector. You cut the wire in half to give you one connector/lead for each headlamp plug that youll be upgrading (left & right), then you can trim the wire down later.

Repair wire:

Comparison of two sizes of the repair wires, with part numbers. The larger one (-133-A) is whats used for this project.

You will need some common tools, and a wire strip/crimp tool (dont try to substitute pliers). In addition to a roll of electrical tape, you should also have a can of StarBrite Liquid Electrical Tape (I got it at Home Depot). For the actual connections you will need a roll of 18 gauge wire (black is good for these runs), some 18-22 gauge crimp-on butt splices, and some 18-22 gauge tap splices:

Procedure:

First you have to remove the sidemarker lights from the bumper. The left side is easy - just open the hood, reach down below the headlamp to the back side of the sidemarker, and release the clip to pop it out from the bumper. The right side is not so easy. You have to carefully pop out the black plastic grill around the right foglamp, and reach up to the back side of the right sidemarker from below. To remove the foglamp grill (not shown here), there are two clips (top and bottom) on the end fartherest from the foglamp that you can release with a flat screwdriver.

Well start with the right side. When you have the light popped out of the bumper, you will find two wires going to it. The brown one is the ground - leave it alone. The other one is the + lead. Pull it out of the split plastic conduit, and use one of the tap splices to connect your new wire to it. Always leave a little extra coil of your new wire tied up in case you have to redo something later:

Then, coat and seal the splice with the liquid electrical tape, and wrap it tightly with regular electrical tape. If done right, it will form a completely waterproof connection. Zip-tie this tightly to the original conduit:

Run the wire in along the existing harness, zip-tying it as you go. Reaching in through the light opening for that fartherest one requres skinny hands and long-nose pliers:

On the right side, there is a rigid plastic cable chase that part of the wiring harness runs through, underneath the neck of the washer-fluid tank. There are two snap clips holding it closed. I managed to get them open and run the wire through the cable chase, then snap it closed again. This keeps it out of the way, completely hidden and protected, and looks original. Getting the snaps open and the wire in there required a heavy wire with a hook bent in the end (made from a clotheshanger):

Now we have the wire up to the headlamp plug, and are ready to attach it. Lets do the left-hand side first, though:

The left light is a lot easier to do. Pop the light out as described above. If you pull the socket out of the lens, you can just pull the harness up where you can reach it from the top by the headlamp. As with the right one, leave the brown (ground) wire alone, attach your new wire with the tap splice, and seal with with the liquid/regular tape as described (photo shows the splice before being sealed & zip-tied).

The left side only takes a short run of wire, zip-tied to the existing wiring harness, to reach the headlamp plug. Now were going to install the new female connector into the headlamp plug.

Remove the plug from the headlamp assembly. Theres a little cap around the back side of the plug, release two clips and take it off (not shown here). Locate position 10 - it should have a rubber plug in it with no wire present. Use a small nail in a pair of locking pliers to pluck the rubber plug out:

Using the same nail, pierce the rubber plug lengthwise. Its already partially started, so youll be able to see what to do:

Pass the new repair wire through the hole in the rubber plug, making sure its in the orientation shown here:

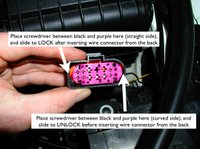

Now you have to get the new female connector into the headlamp plug. You first have to unlock the plug. If you look closely at the purple part of the plug, youll see an arrow molded into it showing the lock direction. Stick a flat screwdriver between the purple part and the surrounding black part on the CURVED side of the plug, and slide the purple part (it moves less than 0.5mm) until it clicks.

Then you can insert the new female connector into position 10 from the back side of the plug, until it clicks in firmly. It only fits in one way - you can figure it out. If you cant get it all the way in until it clicks, make sure you unlocked the purple part as described above. When finished, tt should look from the front just like the others in the plug, and you should seat the rubber plug into the hole behind it so that it looks like the other wires (make sure you slide the purple part the other way to lock it again):

Use a butt-splice to join the wire you ran from the light to the end of the repair wire you just installed in the plug. Youll need to do some trimming, and the splice should look like this:

Again, seal the splice. Dont use too much tape, so you can squeeze it into the split plastic conduit, then zip-tie it securely together. Snap the cap back around the back of the plug (shown here completely together and ready to plug in):

Replace the plug in the headlamp. (If it wont fit in, did you lock the purple part as described above after installing the connector?) Reassemble and replace the sidemarker light into the bumper.

Repeat the process for wiring the plug on the right headlamp.

Test, and you should have....

...working city lights!

If you do this mod, please email me and let me know how it goes. Photos of your wiring steps are appreciated - Im curious how other people replicate this process.

Tuesday, April 2, 2013

Audi A4 XM Radio Install

I spend a lot of time in the car and for those times Im stuck sitting in traffic its nice to have music to keep me occupied. I have a 6-disc changer loaded up with music which I use but I always forget to swap out CDs. Local radio pretty much sucks and I hate hearing commercials every 7 minutes. And, since Im a Jazz fan Im pretty much out of luck as there are no commercial Jazz stations in my area. Enter XM radio. XM radio is a satellite based system that offers 100 channels of music/news etc, many of which are commercial free. Ive lucked out as all the channels I listen to so far are commercial free. :) Unfortunately, you have to subscribe to the service for $9 per month but Ive found it to be $9 well spent. XM touts the music as "digital quality" (whatever that means). Compression artifacts are audible on some types of music with the artifacts most audible on stuff like cymbals or the like which sound a bit shimmery instead of solid. I should mention Im very picky about compression artifacts... even when Ive pointed it out to some passengers they cant hear it but trust me, its there. That said, Im still very happy with the service--Ive found no reason to listen to regular broadcast radio or CDs for several months. The programming has been excellent, sound quality is good--two thumbs up.

I was worried that since the service requires line of sight to one of the two satellites for operation that Id experience frequent service drop-outs. In the two months Ive had it up and running Ive had a glitch or two but no significant service problems and even sitting stopped under an overpass hasnt posed a problem (quite suprisingly). Rain and cloud cover have not been an issue either. Of course, it does not work in parking garages but thats a minor inconvenience.

I decided to leave the existing stereo in place and use an RF modulator based unit that hooks into the car radio antenna. With this type of unit you simply tune the radio of the car to a specific station (which you choose) and the XM radio plays over that station. I opted for a Pioneer GEX-FM903XM. Cost for the radio and antenna were right at $300.

I should mention that the installation of the RF modulator had a dramatic effect on FM radio reception--its very weak. Im told I need to get different antenna cable since the factory antenna is amplified. Ill be getting one of these amplified adapter cables which is supposed to solve the problem. Im in no big hurry though... I never listen to broadcast radio anymore.

Thanks to hakamarob for his assistance on this install.

The Install

I mounted the XM decoder on the underside of the deck in the trunk. The decoder requires 12V+, a switched 12V+ and ground. My car is equipped with a Bose radio so all the power requirements were available at the Bose amp on the left side of the trunk. If you dont have Bose youd need to run the power lines from the front of the car.

To gain access to the power connector for the Bose, remove the trim across the rear of the trunk (philips screws) and pull the carpet side panel loose a bit (its just snapped in with metal clips).

Look in front of the CD changer behind the carpet--the brown connector is plugged into the Bose amp. Pin out for the connector. If you unhook the connector from the amp the harness is long enough to pull out so you can work on it. Use the Red/Blue for main power and the small white for switched power. Attach the ground to the body.

I used the Terk SR-2 roof-mount XM antenna and put it on the deck lid. The instructions for the antenna say it should be 6" from the edge but for me it just looked too weird sitting out in the middle of nowhere. I temporarily mounted the antenna where I thought it looked best and used the radio for a few days to make sure I didnt have any reception problems. Reception was fine so I mounted it centered and close to the leading edge of the deck lid. The antenna doesnt block the high-mount brake light as much as the picture would suggest.

For the antenna wiring I routed it to the underside of the deck lid and put the wiring under the deck lid trim (the hazard triangle is sure a pain to put back!!). The path for trunk lock vacuum line near the hinge offers a clean way to get the wiring routed inside the trunk (I hate drilling holes in the body). I made a small cut in the rubber grommet near the tail light (bottom of the picture below), inserted the wire then sealed the cut with silicone to ensure no future water leaks then routed the two antenna wires to the decoder. The antenna has 2 wires, one for satellite signal and one for terrestrial signal if youre in an area that has ground repeaters. Connect the leads to the decoder. Speaking of the antenna wire, sheesh what a pain. The wire lives to tangle about itself and anything it gets near... it twists and tangles around like a snake poked with a sharp stick at every turn. Nasty stuff.

Note: Route the remote display wire and the RF modulator wire from the front to the back. If you start in the rear youll find there is not enough space to get the RF modulator box into the dash (ask me how I know this little tidbit).

Remove the radio. If you choose to disconnect the radio power be sure you have the radio unlock code or youll have no way to unlock the radio from SAFE mode without a trip to the dealer. The factory harness has plenty of wire so you really dont need to disconnect it.

To remove the radio Audi offers a special tool to unlock the radio. Ive found that jigsaw blades (with the teeth filed off) also work. Slide the tools into the slots on the radio face then pull the radio straight out. The slanted edge of the tools must be long side to the outside edge of the radio. The removal tools are available from any Audi dealer parts department for about $8

Put a towel or something over your console and A/C controls to keep the radio from scratching things up.

Remove the kick panel by removing the plug for access to the screw. Also remove the screw near the top of the panel. Then, slide the panel back slightly to release a tab near the door sill joint then lift up and out.

Route the wire for the FM modulator through the radio opening in the dash, under the dash, behind the kick panel then under the door sill panels. Route the wire for the remote display as appropriate for your mounting location. The wires are thin so I didnt bother to remove the sill trim but just tucked them underneath.

Tuck the wiring behind the seat then route to the decoder.

To hook up the RF modulator youll need special cables to connect to the RF modulator box. Audi uses a small flat connector instead of the standard RCAish-looking type connector. The antenna cable set I got from Mobile One audio was labeled specifically for VW/Audi. Youll note that there are two antenna connectors on the back of the radio. Were only interested in the one near the outside edge of the radio.

The Audi specific cables.

Neatly stuff all the wiring in the dash. I wrapped the modulator box in foam to prevent it from rattling around and making noise. Re-install the radio.

I placed the remote display just under the center vents. Double sided tape holds it in position. My original plan was to put it down in front of the ashtray but it was too hard to read so high up on the dash is its home for now. I have ideas of how to integrate it better into the dash but that may come later if I have the time.

Overall, a very nice addition. Ive heard music I havent heard in years and I often find myself sitting and listening after arriving at my destination. Highly recommend.